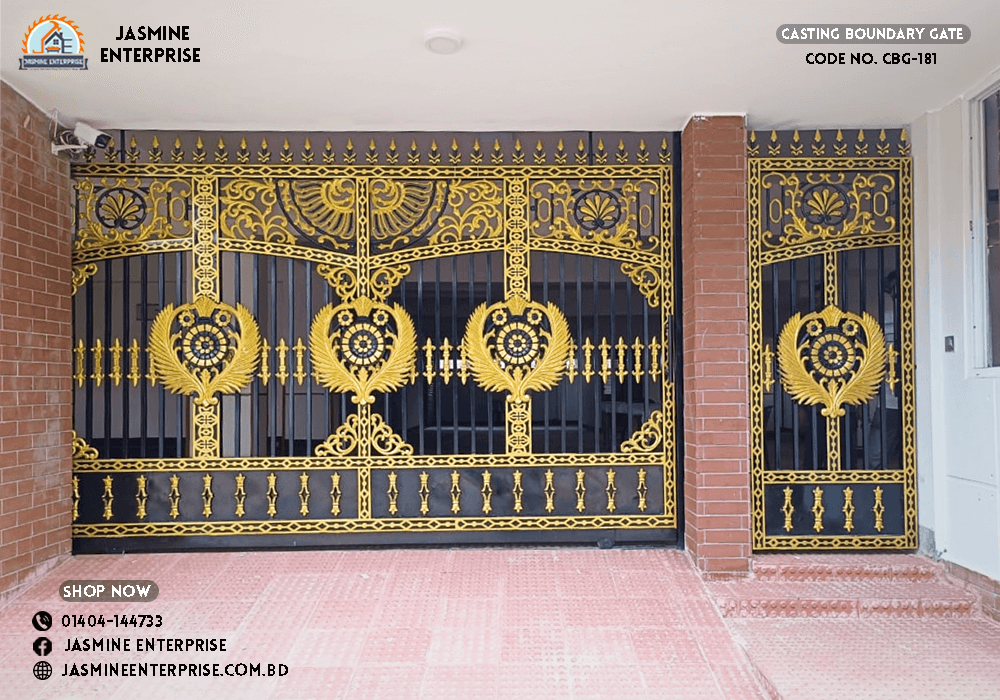

- Casting Gate Design in Bangladesh

- Model No: CBG-181

- Delivery Time: 20-50 Days

- Shipment: Free in Dhaka city

- Product Unit: Price per pcs.

- Paint: Powder Coated Paint

- Materials: Iron, Cast Iron, Steel

- Size: H 08′ x L 12′ or As your requirement

- Metal Type: Steel, Wrought iron casting

- Open Style: Swing, Sliding

- Even for more details, you can contact me over the phone – 01785639373, 01404144733

Casting Gate Design in Bangladesh

Casting gate design in Bangladesh optimizes metal flow and solidification in molds. Expert designers focus on quality and efficiency in production. In the world of manufacturing, casting gate design plays a critical role, particularly in Bangladesh’s growing industrial sector. The design of casting gates directly affects the quality of casted components, making it a vital consideration for foundries and manufacturers. With an emphasis on reducing defects, improving strength, and enhancing surface finish, the design process requires meticulous planning and expertise. Bangladeshi engineers and foundry experts leverage local resources and international standards to create gate designs that ensure uniform filling and cooling, which is essential for producing top-notch cast metal products. As the country’s industries continue to expand, the need for optimized and sustainable casting gate design becomes ever more prevalent, reflecting Bangladesh’s commitment to quality and competitiveness in the global market.Factors Affecting Casting Gate Design

The type of casting process significantly influences the design of casting gates. Each process, such as sand casting, die casting, or investment casting, has its own set of requirements that dictate the gate’s dimensions, shape, and overall layout. Metal characteristics also play a vital role in gate design. The properties of metals like aluminum, iron, or bronze define the thermal and filling behaviors, directly impacting the gating system to ensure quality castings. Casting complexity involves the intricacies within the cast component. Highly complex shapes require a carefully thought-out gate design to ensure proper metal flow and avoid defects. When considering casting volume, high production runs may necessitate a more robust and efficient gating system to maximize output and maintain consistent quality. Focusing on time and cost constraints is also critical. Efficient gate design can drastically reduce waste, improve cycle times, and thereby save both time and costs associated with the production.Design Considerations For Casting Gate Design

The gate size and shape are pivotal to a successful casting process, directly affecting the quality of the final product. Optimal gate dimensions can significantly mitigate turbulence and material wastage, ensuring a seamless flow of molten metal. The strategic number and placement of gates facilitate a uniform material distribution, vital for maintaining structural integrity. An equitable spacing of gates can also reduce the risk of hotspots and shrinkage, often leading to internal defects. A controlled gate velocity and flow rate are essential to prevent oxidation and porosity, ensuring the molten metal fills the mold accurately without creating gas pockets or inclusions. This precision greatly influences the forging of a defect-free casting. Solidification factors play a critical role in defining gate design, as they affect thermal gradients and cooling rates, which are crucial for dimensional stability post-casting. The mold filling characteristics must be analyzed to determine optimal chilling and gating strategies. Understanding common casting defects and remedies is fundamental. Implementing preventative measures within the gate design can significantly minimize common issues such as misruns, cold shuts, and inclusions.

Frequently Asked Questions Of Casting Gate Design In Bangladesh

What Is The Cost Of Making Steel Gate?

The cost of manufacturing a steel gate can vary widely, starting from approximately $100 to $2,000, influenced by size, design, and labor expenses.What Is A Casting Gate?

A casting gate is the channel in a mold through which molten material flows into the cavity. This gate controls the flow speed and reduces defects.What Is Casting Gate Design?

Casting gate design involves the methodology and geometry used to direct molten metal into mold cavities. In Bangladesh, it’s tailored to local manufacturing practices and available resources, ensuring efficient and defect-free casting results.Why Is Gate Design Crucial In Casting?

A properly designed gate system ensures consistent metal flow, temperature control, and solidification. This directly affects the casting quality, reducing defects such as turbulences and cold shuts, which are critical for the casting industry in Bangladesh.Conclusion

Navigating the nuances of casting gate design demands attention to detail and local expertise. Bangladesh offers unique possibilities for quality and cost-efficiency in this field. With the right partnership and knowledge, the potential for innovation in casting gate manufacturing is vast. Embrace the craftsmanship of Bangladesh for your next project – the gateway to success awaits. Contact us now to get started on designing the best Swing table Design just for you! If you would like more information about this product, don’t hesitate to get in touch with us today via call on +88 01404144733Be the first to review “Casting Gate Design in Bangladesh -181”

Related products

-38%

Steel Center Table

-16%

Hostel Bed

-10%

Computer Table

-19%

Shoe Rack

-25%

Shoe Rack

-45%

Steel Chair

-22%

Steel Dining Table

-14%

Steel Home Furniture

-20%

Steel Home Furniture

Reviews

There are no reviews yet.